Explainer: What’s Chip Binning?

You exact supplied a brand recent CPU or graphics card, and fired it up for your PC. It appears to trudge beautiful cold, so you are trying a chunk overclocking. The gigahertz climb higher and better, and it looks luxuriate in you admire got got purchased yourself one thing particular. Or no longer it’s surely no longer supposed to be luxuriate in this?

So that you just trudge to the web to fragment your pleasure of hitting the silicon jackpot, and within a number of posts, any individual publicizes that you just admire got got purchased yourself “a binned chip“.

Now, when you are picturing an engineer rummaging about in a trash can and proudly pulling out a golden tag, then you positively in actual fact want to be taught this explainer! Welcome to the magical world of processor fabrication and chip binning.

TL;DR: What’s chip binning?

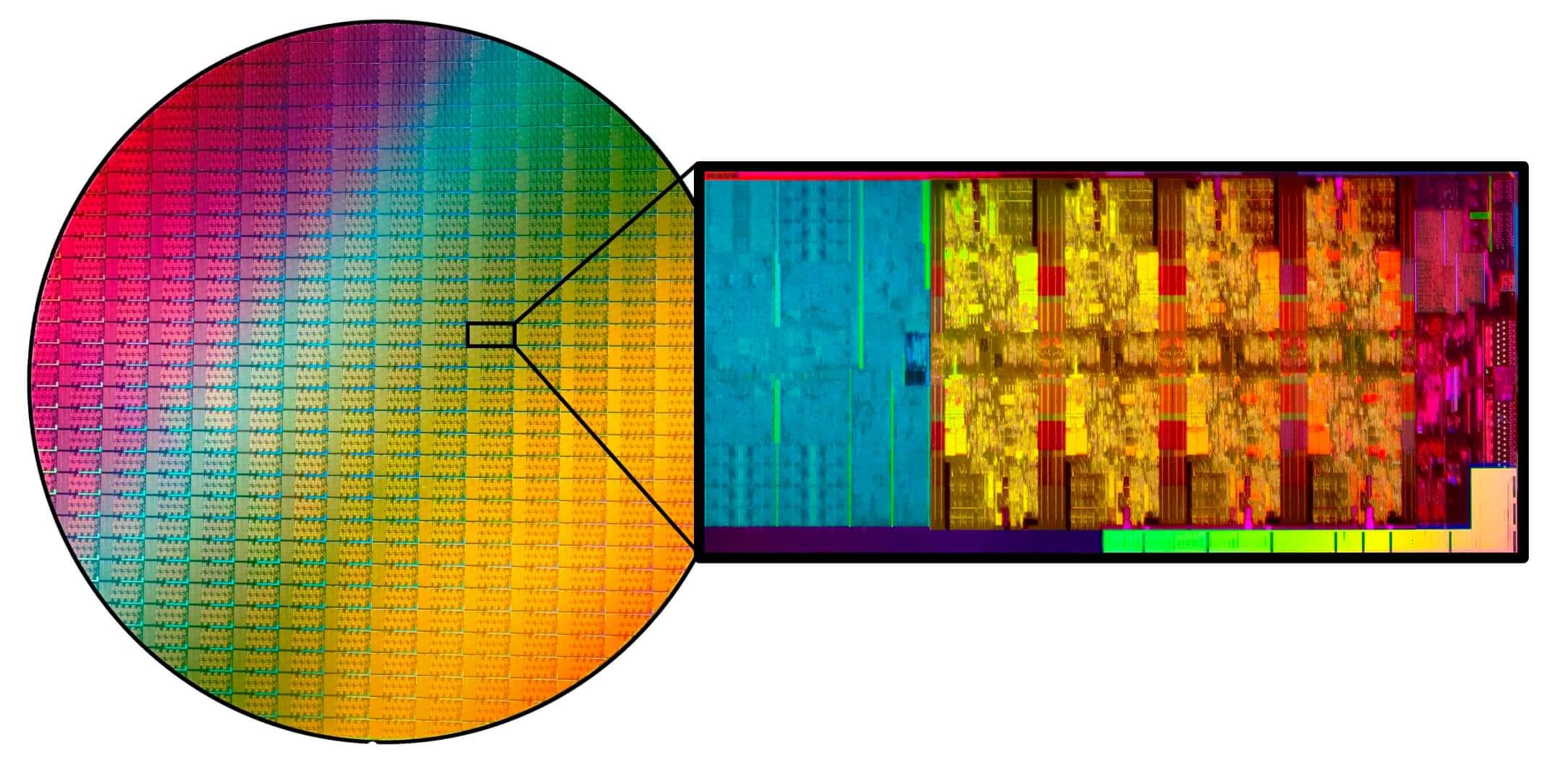

The cleanest manufacturing facility within the world? Image: Intel

- Chip manufacturing is no longer supreme. Every chip ragged for your PC (to illustrate, the CPU or GPU), for your cell phone, or for your automobile all lag thru a preference direction of. Here is because after manufacturing some chips will invent higher than others.

- All chip makers luxuriate in Intel, AMD, and Nvidia incorporate a preference direction of the set up higher performing chips are designated to be supplied as dearer units (offering higher clock speeds, more cores, etc) and no more-than-supreme factors but quiet utterly utilizable silicon would possibly perchance well even be supplied as lower performing processors with cores disabled, or lower speeds.

- Lots of examples: if the chip can no longer trudge at 2 GHz, then you positively put it on the market as a chip that runs at 1.5 GHz. Or if a CPU reveals defects within the constructed-in graphics part, you put it on the market as a CPU with out constructed-in graphics.

- Chip binning is a stage within the manufacturing of all microprocessors and DRAM chips the set up this separation happens.

- Whereas abnormal chip binning is supposed to work to the advantage of producers, if there is too remarkable demand for a given cost/mainstream model, chances are you’ll well perchance also just catch fortunate and pause up with very capable silicon/chip that’s been supplied as a more cost effective part.

- Binning furthermore improves the yield of a wafer because more silicon would possibly perchance well even be utilized and supplied, reducing manufacturing costs. This article goes in higher depth in regards to the chip manufacturing direction of and why certain choices are made.

Wafers to die for

All chips are comprised of discs of extremely-pure silicon, layered with metals, insulators, and semiconducting offers, whether or no longer it’s a feeble CPU, specialised graphics processor, or DRAM to change into draw reminiscence.

Your total direction of is hugely complex and the manufacturing crops required to originate the most modern chips in abundant volumes, cost billions of bucks. These discs are is named wafers and the likes of Intel, GlobalFoundries, and TSMC churn out hundreds and hundreds of them yearly.

Interior a trendy chip fabrication plant. Image: TSMC

The greatest quality tools are distinguished to make certain that the closing product suits the extremely-correct plans from the engineers who designed the chips.

To cast off every little thing as end to to perfection because it’ll even be, factories’ manufacturing areas are a chunk pressurized to preserve airborne micro organism and dirt particles out of the rooms. Workers build on defending equipment to make certain as shrimp of their pores and skin cells and hair can enter the equipment.

A finished wafer is an a part of beauty, and incredibly precious, too.

Every costs hundreds of bucks to manufacture, and the total fabrication direction of – from silicon ingot to product – takes months from open to pause. Every chip (furthermore is named a die) that can even be taken from the disc and supplied is distinguished to convalescing the money spent to originate them.

A 11.8 lag (300 mm) wafer of Intel ninth-gen Core processors

To catch them out, the wafer is sliced up the usage of a diamond noticed, but an inexpensive share of it’s utterly scrap, as chips alongside the edge exact are no longer full. Wherever from 5 to 25% of the wafer (the amount is dependent loads on the scale of the chip) will catch thrown away.

The the rest then gets mounted on a circuit board kit and presumably lined with a heat spreader, to indirectly change into the CPU we’re all unsleeping of.

Core (in)equality

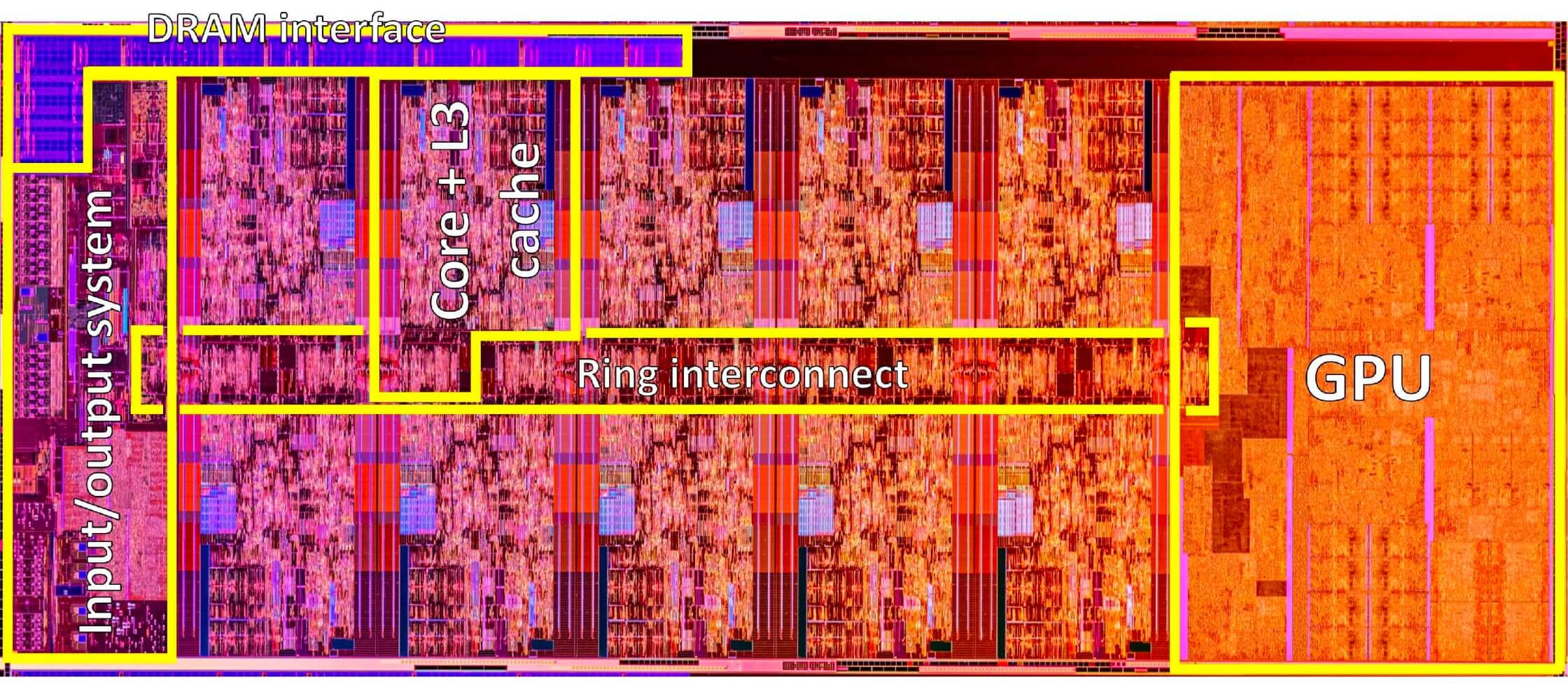

Let’s spend a explore at one of Intel’s rather trendy processors – the passe Core i9-10900Okay flagship, which has 10 cores and an constructed-in GPU.

The list below reveals how we on the total know and peek such PC factors, but if we can also prise off the warmth spreader and spend a battery of tools to delve into the center of the chip, it would possibly perchance perchance perchance most likely well presumably explore very assorted.

The genuine CPU is a cityscape of good judgment blocks, SRAM storage, interfaces, and verbal change buses – in a single chip on my own, there are billions of particular person digital factors, all working in synchronized harmony.

Moreover be taught: Anatomy of a CPU

The labelled list below highlights a number of of the major areas – on the a long way left is the I/O draw, containing the DDR4-SDRAM reminiscence, PCI Say, and converse controllers. Moreover packed in there would possibly perchance be the draw that manages the verbal change ring for all of the cores. Valid above the I/O part is within the interface for the draw reminiscence and on the opposite facet of the die, we can peek the constructed-in graphics chip, the GPU. Or no longer it’s miles never associated what Intel Core processor you catch, these 3 factors will all be portray.

Stuffed between all of these are the CPU cores. Every is a carbon reproduction of the opposite, elephantine of units to crunch numbers, transfer knowledge around, and predict future instructions.

Lying both facet of a core are two strips of Stage 3 cache (the lower ranges are deep within the core), with every offering 1 MB of high tempo storage.

It is possible you’ll well perchance presumably also think that Intel makes a brand recent wafer for every CPU they promote, but a single ‘i9-10900’ disc will form chips that can doubtlessly pause up in someone of the next units…

| Model | # Cores | # Threads | Nasty Clock | All Core Turbo | Turbo Enhance | Total L3 Cache | PL1 TDP |

| i9-10900Okay | 10 | 20 | 3.7 | 4.8 | 5.1 | 20 | 125 |

| i9-10900KF | 10 | 20 | 3.7 | 4.8 | 5.1 | 20 | 125 |

| i9-10900 | 10 | 20 | 2.8 | 4.5 | 5.0 | 20 | 65 |

| i9-10900F | 10 | 20 | 2.8 | 4.5 | 5.0 | 20 | 65 |

| i9-10900T | 10 | 20 | 1.9 | 3.7 | 4.5 | 20 | 35 |

| i7-10700Okay | 8 | 16 | 3.8 | 4.7 | 5.0 | 16 | 125 |

| i7-10700KF | 8 | 16 | 3.8 | 4.7 | 5.0 | 16 | 125 |

| i7-10700 | 8 | 16 | 2.9 | 4.6 | 7.7 | 16 | 65 |

| i7-10700F | 8 | 16 | 2.9 | 4.6 | 4.7 | 16 | 65 |

| i7-10700T | 8 | 16 | 2.0 | 3.7 | 4.4 | 16 | 35 |

| i5-10600Okay | 6 | 12 | 4.1 | 4.5 | 4.8 | 12 | 125 |

| i5-10600Okay | 6 | 12 | 4.1 | 4.5 | 4.8 | 12 | 125 |

| i5-10600 | 6 | 12 | 3.3 | 4.4 | 4.8 | 12 | 65 |

| i5-10600T | 6 | 12 | 2.4 | 3.7 | 4.0 | 12 | 35 |

| i5-10500 | 6 | 12 | 3.1 | 4.2 | 4.5 | 12 | 65 |

| i5-10500T | 6 | 12 | 2.3 | 3.5 | 3.8 | 12 | 35 |

| i5-10400 | 6 | 12 | 2.9 | 4.0 | 4.3 | 12 | 65 |

| i5-10400F | 6 | 12 | 2.9 | 4.0 | 4.3 | 12 | 65 |

| i5-10400T | 6 | 12 | 2.0 | 3.2 | 3.6 | 12 | 35 |

The ‘Nasty Clock’ measured in GHz (gigahertz) is the bottom assured frequency the chip will trudge at, it’s no longer distinguished what load it’s beneath. The ‘All Core Turbo’ is the maximum frequency that every person of the cores can trudge at together, but no longer essentially preserve at for extraordinarily prolonged. Or no longer it’s a identical factor for ‘Turbo Enhance’ other than here is exact 2 cores.

PL1 TDP stands for Vitality Stage 1 – Thermal Construct Vitality. Or no longer it’s how remarkable heat the CPU will form whereas running at its Nasty Clock beneath any load. It’ll form loads bigger than this, but it would possibly perchance perchance perchance most likely well presumably restrict what speeds the chip will trudge at and when plugged into a motherboard, the designers of them can also just restrict how remarkable energy the chip can soak up, to prevent this.

Fashions with codes ending with an F admire a disabled GPU; Okay signifies it has an unlocked clock draw (so chances are you’ll well perchance also with out yelp overclock it), and T denotes low energy. These are exact the desktop CPUs – some will pause up as Xeon units which are aimed at the official market, within the catch of workstations or runt servers.

So that’s 19 units from exact one invent – how and why does a single chip pause up turning into so many different sorts?

Or no longer it’s an wicked world

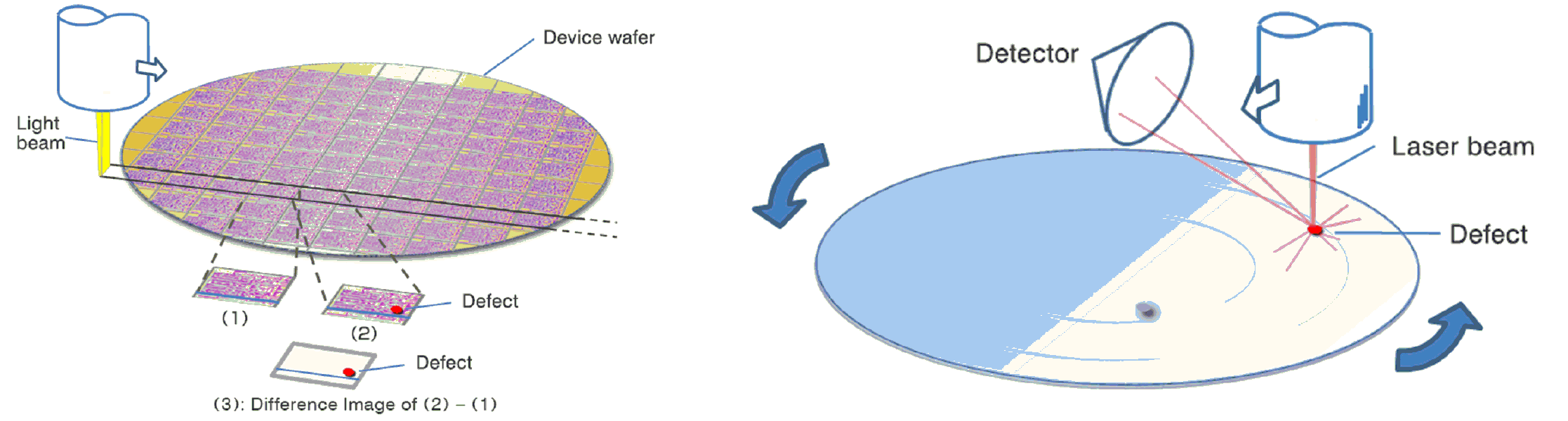

As improbable as chip fabrication crops are, neither they nor the skills and offers ragged are 100% supreme. There’ll continuously been some nano-scale motes of detritus, both within the plant or deep within the raw silicon and metals ragged. Irrespective of how robust they struggle, producers can no longer originate them utterly properly-organized and pure.

And when you are trying to originate up factors which would possibly perchance well perchance be so runt, that entirely high powered electron microscopes allow you peek them, nothing rather behaves exactly because it’ll also just quiet attain.

Down within the nanometer world, quantum behaviour turns into a long way more noticeable and randomness, noise, and other system defects attain their most effective to upset the at ease sport of chip-Jenga. All of these considerations conspire against processor makers, and the tip results are classed as defects.

Image comparability vs gentle scattering techniques for discovering defects. Image: Hitachi

No longer all defects are serious – they will also just exact trigger a particular a part of the chip to trudge hotter than it’ll also just quiet, but if it’s in actual fact heart-broken, then a total part would possibly perchance well perchance be utterly junk. The first factor producers attain is scan the wafers to explore the defects within the first set up.

Machines dedicated to hunting out these considerations are ragged after a wafer has been fabricated but sooner than it’s sliced up into particular person chips. The dies or total wafers that portray up as having considerations are flagged, so they will even be dwelling aside for further examination.

Nonetheless even these steps are no longer going to have every minor blemish and glitch, so after the silicon objects are within the reduction of from the wafer and mounted onto their programs, every of them goes off for even more testing.

No longer all packing containers store garbage

When Intel and others take a seat correct down to verify the quality of their processors, they dwelling the chips up to trudge with a dwelling voltage and at a undeniable clock tempo; whereas the die goes thru a differ of benchmarks, designed to emphasise all of the a quantity of sections, the amount of electrical energy consumed and heat produced are carefully measured.

What they will web is that some chips trudge exactly as required, whereas others are higher or worse.

Some chips can also desire a higher voltage to be utterly stable, other chips’ insides can also just form too remarkable heat, and certain some merely received’t attain the distinguished standards elephantine pause.

Assembling processors sooner than closing testing and inspection

The same explorations are performed to the processors identified with having defects, but sooner than here is implemented, extra tests are performed to transfer attempting what sections of the chip quiet work and what bits are scrap.

The pause results of here is that the invaluable output of a wafer, called its yield, generates a differ of dies that they would possibly be able to even be categorized on the premise of their functioning factors, stable clock frequencies, required voltage, and heat output. The establish for this sorting scheme? Chip binning.

No dies are actually thrown into huge plastic packing containers – the phrase comes from statistics, the set up a distribution of numbers would possibly perchance well even be organized into groups called packing containers. As an illustration, population surveys about age distribution can also spend the packing containers 0 to 5 years passe, 6 to 10, 11 to 16, etc.

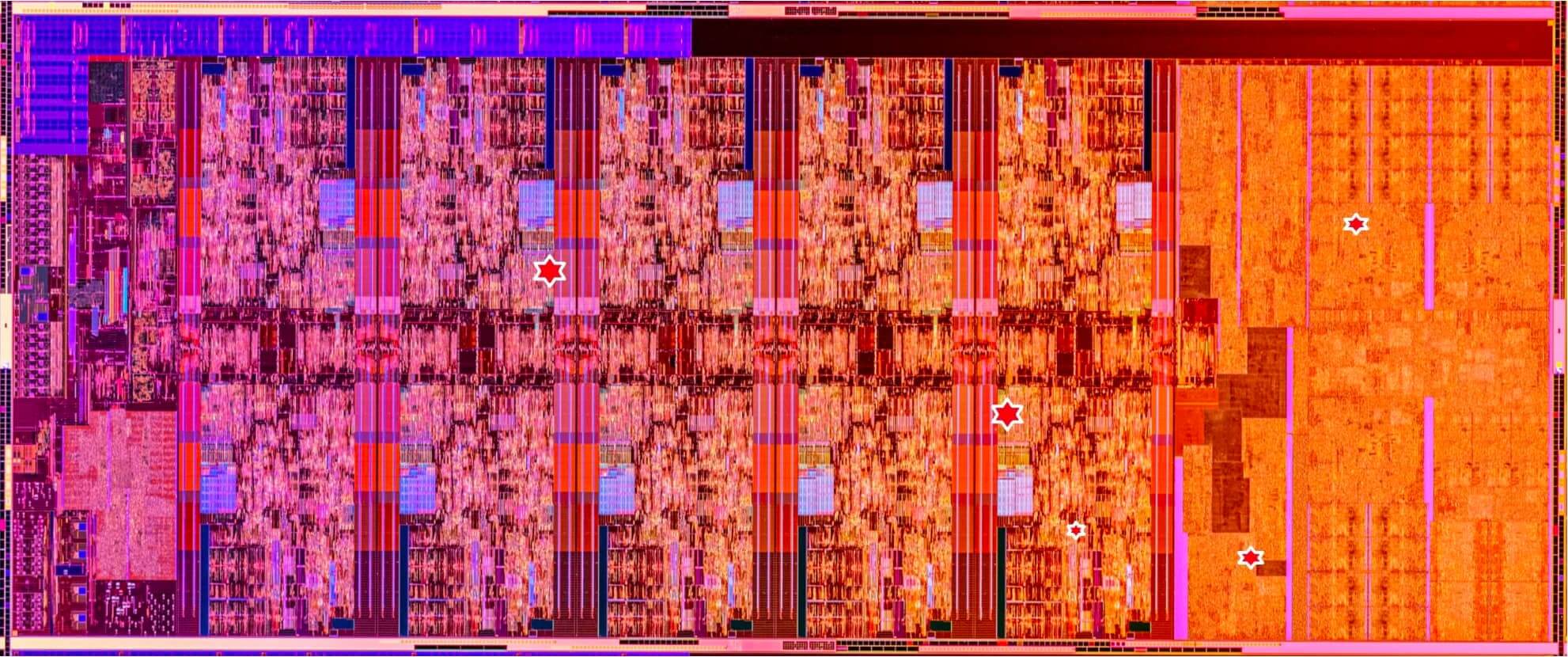

The identical is done for wafers, and within the case of our i9-10900Okay example, a number of of the packing containers would possibly perchance well perchance be for preference of working cores, clock frequency differ exact thru which the CPU is stable, and heat output at a undeniable clock.

Let’s factor in that a Core i9-10900 chip is totally tested and stumbled on to admire a number of distinguished defects, as indicated above. Two of the cores and the GPU are damaged to a level the set up they exact can no longer characteristic properly.

Intel would then disable the kaput sections and flag it up as being a chip for the Core i7-10700 differ, particularly an F model. Nonetheless then it wants to be tested for clock speeds, energy, and balance. If the chip hit the distinguished targets it would possibly perchance perchance perchance most likely well presumably preserve as an i7, but if it would possibly perchance perchance perchance most likely well perchance not rather attain these targets, one more 2 cores will doubtless be disabled and the die ragged for a Core i5 model as an alternative.

All issues actually apt as, chip binning hugely improves the yield of a wafer because it scheme that more dies would possibly perchance well even be utilized and supplied.

Within the case of the 10th-gen differ of Core processors, Intel did admire a separate wafer invent for the Core i5, i3, and Pentium/Celeron ranges. These launch as 6 core chips and then catch binned upright down into 2 core offerings.

Product demand can incessantly outstrip manufacturing skill, hence why the 10-core wafers are ragged to lend a hand private in orders. Generally, completely purposeful dies admire sections switched off, exact to make certain there would possibly perchance be ample output from the factories. That does imply it’s a sport of silicon lottery as to what die you’re in actual fact getting, when procuring for a explicit model.

All issues actually apt as, chip binning hugely improves the yield of a wafer because it scheme that more dies would possibly perchance well even be utilized and supplied. Without it, Intel’s genuine garbage packing containers would possibly perchance well perchance be overflowing with scrap silicon.

Are no longer binned CPUs particular?

Love so many terms in computing, chip binning has change into synonymous with one thing other than its popular which scheme. On-line stores every now and then promote hand-picked, particular CPUs (people that overlock to an insane level or trudge cooler than the bottom of Pluto) as “binned CPUs.” The reality is all chips are binned, just because they will also just quiet be.

Really, there is nothing to pause a retailer from binning the chips they have: binned-binned CPUs, someone?

AMD and Intel processors can also just quiet be purchased in bulk (trays that contains dozens, if no longer hundreds, of chips), and likewise chances are you’ll well perchance also take a seat down with a check computer and verify out every person – overclock or undervolt them, tale their temperatures, etc. The greatest of the batch can also then be supplied on as being particular, and the retailer can also rightly class them as “binned.” Naturally, all of this extra testing costs time and effort, so the retail ticket of the product is increased to reflect this.

Are these so-called binned chips extra particular somehow? Yes and no. Every single chip ragged for your PC, cell phone, automobile, etc admire all been thru some more or much less preference direction of. Or no longer it’s exact one more stage within the manufacturing of all microprocessors and DRAM chips. Meaning the one you want CPU or GPU that runs surprisingly cold or overclocks luxuriate in exasperated is exact one more die, from one of the distinguished hundreds of hundreds of wafers, churned out by factories all the scheme thru the world.