‘Mass customisation’: Tranquil 3D printing tech brings more flexibility to alternative meat and seafood manufacturing

3D printing has been described because the ‘tech of the prolonged stir’. For Revo Foods, it is very mighty the tech of the designate.

Revo produces mycoprotein meat and fish potential choices by 3D printing technology. Severely, it these days produced and released the ‘world’s first’ 3D-printed smoked salmon fillet final year.

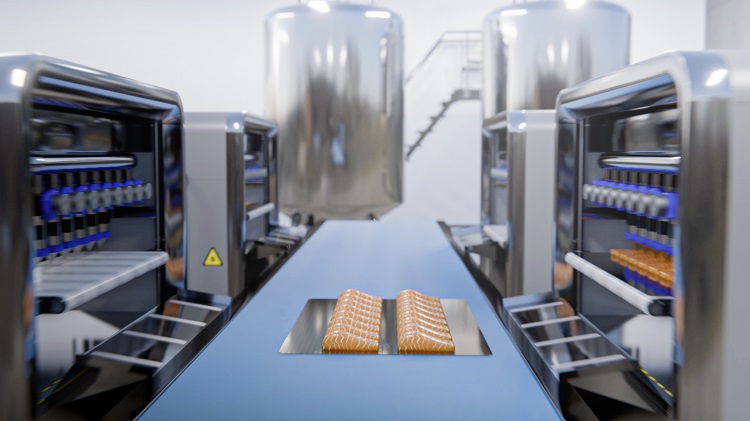

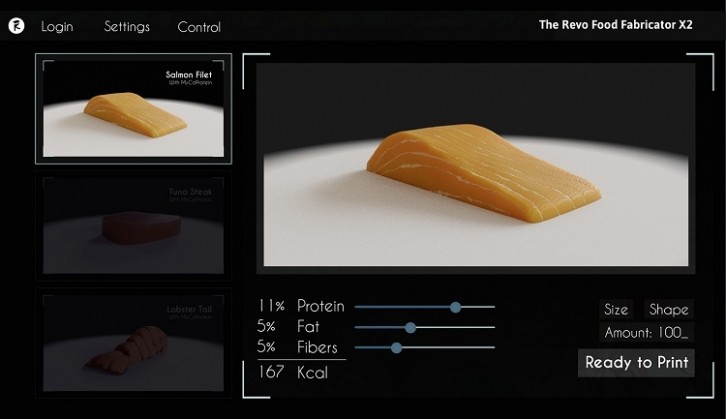

Now, the company has presented a brand new printer, the ‘Food Fabricator X2’, which might possibly customise shapes, constructions and textures, and has a multi-nozzle system that will seemingly print a couple of merchandise right away.

Revo is also planning to upscale manufacturing with the money it hopes to raise from a deliberate free up of digital shares to the general public.

Continuous manufacturing

Revo’s new technology enables continuous meat analogue manufacturing which, the company says, is the first time mass manufacturing of such merchandise has been potential with 3D printing.

The corporate’s printer is “an fully new manufacturing machinery to enable the structuring of complex, heterogeneous food objects with 3D applied sciences. 3D Food Printing existed for a whereas, but we developed (and patented) some foremost parts which now enable us to affirm this technology to the industrial scale,” Revo Foods’ CEO Robin Simsa told FoodNavigator.

The corporate’s new extrusion print-head create, shall we embrace, enables a continuous float of materials for the first time. Sooner than this, a more labour-intensive batch task changed into the expose of the day. “With this resolution it is miles potential to work with immense fabric volumes without manual labour input. Clearly, this has a giant fashion on the worth.”

Secondly, the multi-nozzle print head create can manufacture many merchandise at the identical time. “While dosing methods with a couple of nozzles maintain already been in consume within the food industry for decades, here is the first time that this system is being incorporated in a 3D food printing setup.”

At final, a modular stagger and play system connects the manufacturing machines. “This methodology, we are able to enable a modular scale-up of the manufacturing to happen, and digitally retain watch over your entire manufacturing when it comes to diversified product kinds and designs. No more hardware modifications are wished between diversified product kinds, which is but any other immense advantage.”

3D printing is critically suited to ‘structured’ and ‘complex’ merchandise such as entire lower filets and steaks, Simsa told us, in role of ‘non-structured’ merchandise such as burgers and chicken nuggets. “3D Food Printing is primarily the controlled combination of two diversified food substances into new constructions. Diversified applied sciences (e.g. extrusion) are uncontrolled, subsequently better suited for non-structured merchandise.

“When it involves complex objects, 3D Food Printing is the first technology that in actuality permits the combination of a paunchy segment into the plant-protein fibre matrix, which is the predominant for these merchandise to be triumphant in new sensory stages. In summary, both applied sciences might possibly seemingly neatly be mature for diversified product purposes, and 3D printing is more appropriate for prime-worth, fully structured meat potential choices.”

Customising meat and seafood

While most neatly-acknowledged for its seafood potential choices, Revo Foods also produces meat potential choices. Simsa sees opportunities in both. Namely, that 3D printing will originate merchandise more customisable and more varied.

“There’s a huge interest from huge food producers for “mass customisation”, that methodology the flexibility to manufacture runt batches of individual merchandise for individual customer groups, without primarily resulting in elevated manufacturing costs.

“Exact now, here is inconceivable, on story of all food machinery is built for enormous scale of identical merchandise, but we imagine that with new applied sciences such as 3D food printing and the engaging new merchandise that will seemingly neatly be created relish this, there is a brand new inventive impulse for food product builders and the food industry as a entire on the methodology. Why not introduce some loopy new shapes and constructions or combination of diversified substances which were earlier than finest potential in Michelin-valuable particular person restaurants, but not as a particular person aesthetic in supermarkets? We imagine that will seemingly neatly be a great future to work towards.”

The first advantages of the tech, believes Simsa, are: its flexibility, as it might possibly possibly maintain many varied forms of merchandise with a single machine; its controllability, being ready to retain watch over the distribution of materials within a product; and creativity, no theoretical limits on the form of product that will seemingly neatly be produced.

Revo’s merchandise are, in role of being plant-primarily primarily based, mycoprotein-primarily primarily based as a replace. In accordance with Simsa, here is the entire vogue down to three components: neatly being, model, and particular person records.

“Mycoprotein has a total amino acid profile and a in fact orderly model. Also, shoppers know relating to the advantages of fungi and mycoprotein, and to this level we had an improbable particular person reception primarily primarily based on this substances, and heaps of different folks procuring the product particularly for that reason. Also, we are able to also create Nutri-Salvage “A” in our merchandise attributable to the utilization of this ingredient,” he told us.

Investment, upscaling and diversification

After the free up of its first product, ‘THE FILET – Inspired by Salmon’, in September final year, Revo is rising in self perception, and has presented plans to introduce digital shares to be sold by the general public.

“We’re now constructing all the pieces for our next step in upscaling: A manufacturing plant with a few a entire bunch output, which we are able to be conscious unless summer season 2024 in Vienna, and initiate entering food retail on a huge level,” Simsa told FoodNavigator.

The corporate is also planning on expanding from simply straightforward meat and seafood entire cuts to diversified merchandise as neatly. “While we were completely centered on the consume of our technology for meat potential choices within the starting, we were contacted by a couple of companies over the final years which might possibly seemingly neatly be drawn to the consume of this technology for diversified product kinds (e.g. snacks, pasta or stuffed meals with loopy shapes or kinds or personalized merchandise). We imagine there is a big worth in enlarging our technological level of interest and providing our manufacturing technology to diversified food manufacturers as neatly, starting from the discontinue of 2024.

“This methodology, we might possibly seemingly be particular that a brand new inventive impulse for the choice meat industry, but also for the broader food industry itself, enlarging our consume-case also as a technology provider. Our operate is to turn out to be the leader in 3D manufacturing instruments for the food industry, which might possibly seemingly neatly be a specific segment business at the second, but one who is stride to turn out to be very precious because the probabilities of this technology turn out to be obtainable to more producers.”