JFE Steel and Hitachi Jointly Started Providing Solutions for the Steel Change

– Solving manufacturing challenges with consulting and computerized chilly-rolling flatness retain watch over procedure –

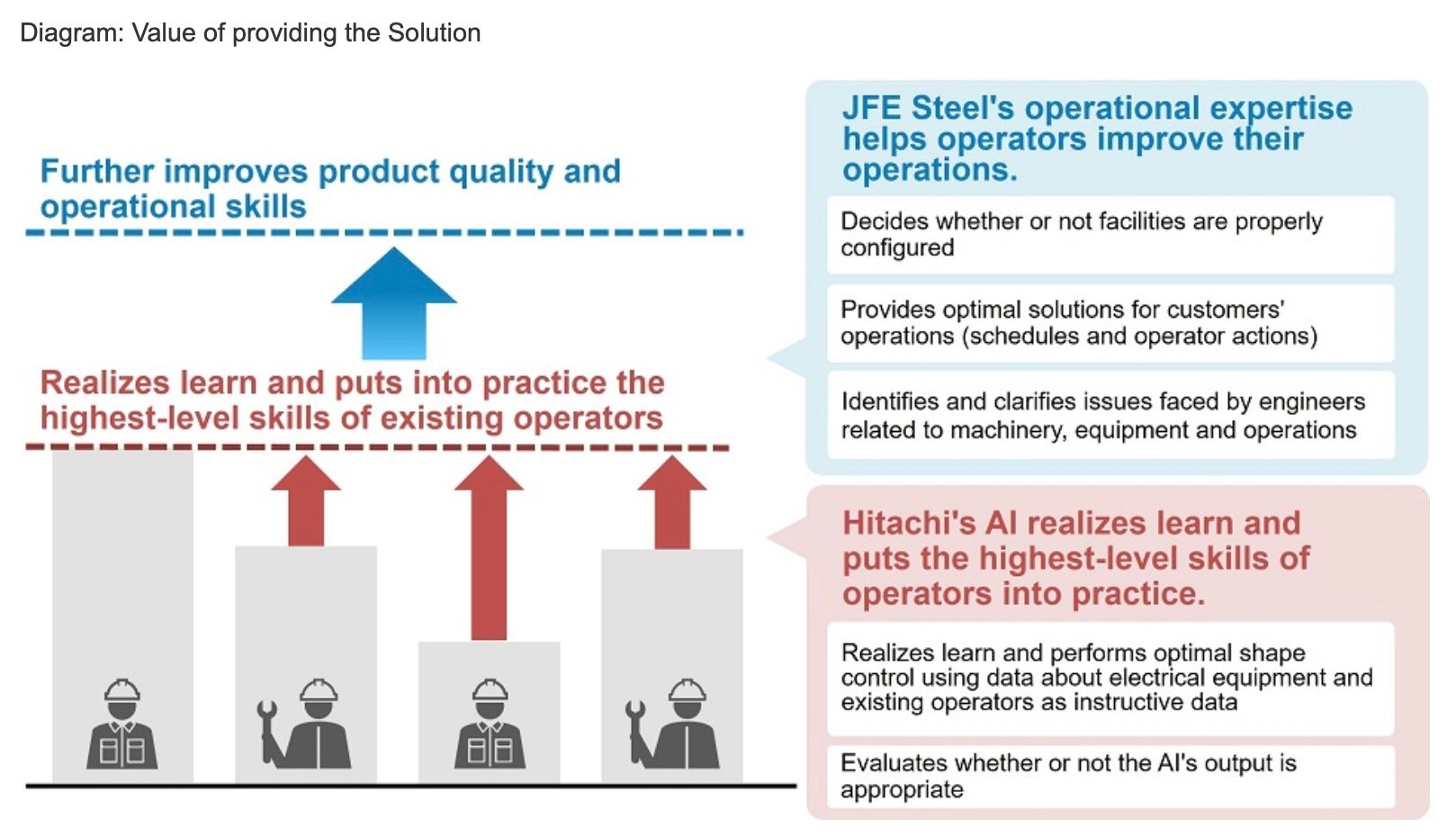

TOKYO, Mar 26, 2024 – (JCN Newswire) – JFE Steel Company (“JFE Steel”) and Hitachi, Ltd. (TSE: 6501, “Hitachi”) lately announced that they occupy got began to maintain an answer (the “Solution”), which mixes JFE Steel’s consulting applications and Hitachi’s computerized chilly-rolling flatness retain watch over procedure, to steel companies in each and every Japan and in a foreign country. The Solution parts the combo of Hitachi’s procedure, which makes exhaust of an man made intelligence (AI) to robotically retain watch over the steel sheet knocking down direction of by a rolling mill, and JFE Steel’s consulting applications (regarding the introduction of programs and optimal operations), a provider that leverages its excessive-degree operational journey in systems that meets buyer wants.Traditionally, wavy steel sheets are flattened by a rolling mill that ought to be finely adjusted manually by skilled operators. The Solution will take care of relevant components such because the deterioration of yields ensuing from variations in operators’ technical skills and the switch of expert skills, and besides, assist customers enhance their skills and product quality.

The JFE Community has been working to enhance production efficiency and yields and tremendously enhance labor productivity through the DX-pushed introduction of latest technologies. As successfully as, it has been promoting an answer commercial to maintain a wide fluctuate of clients taking part in manufacturing companies with systems for producing excessive label-added products, which the Community has developed through the operation and management of steelworks, and technological, operational and compare journey to take care of components connected to facility maintenance and environmental load reduction.

Hitachi has been offering Lumada*1 solutions to scramble DX by leveraging products, OT (operational technologies) and IT, which it has developed over decades as a manufacturing firm, besides a wealth of recordsdata and journey (enviornment recordsdata) that it has obtained through the provision of solutions to components faced by customers working in wide areas and domains within the manufacturing alternate. In the steel commercial spot, it has been globally promoting products and services, direction of traces, retain watch over programs and other tools for vegetation as a complete procedure.

Background

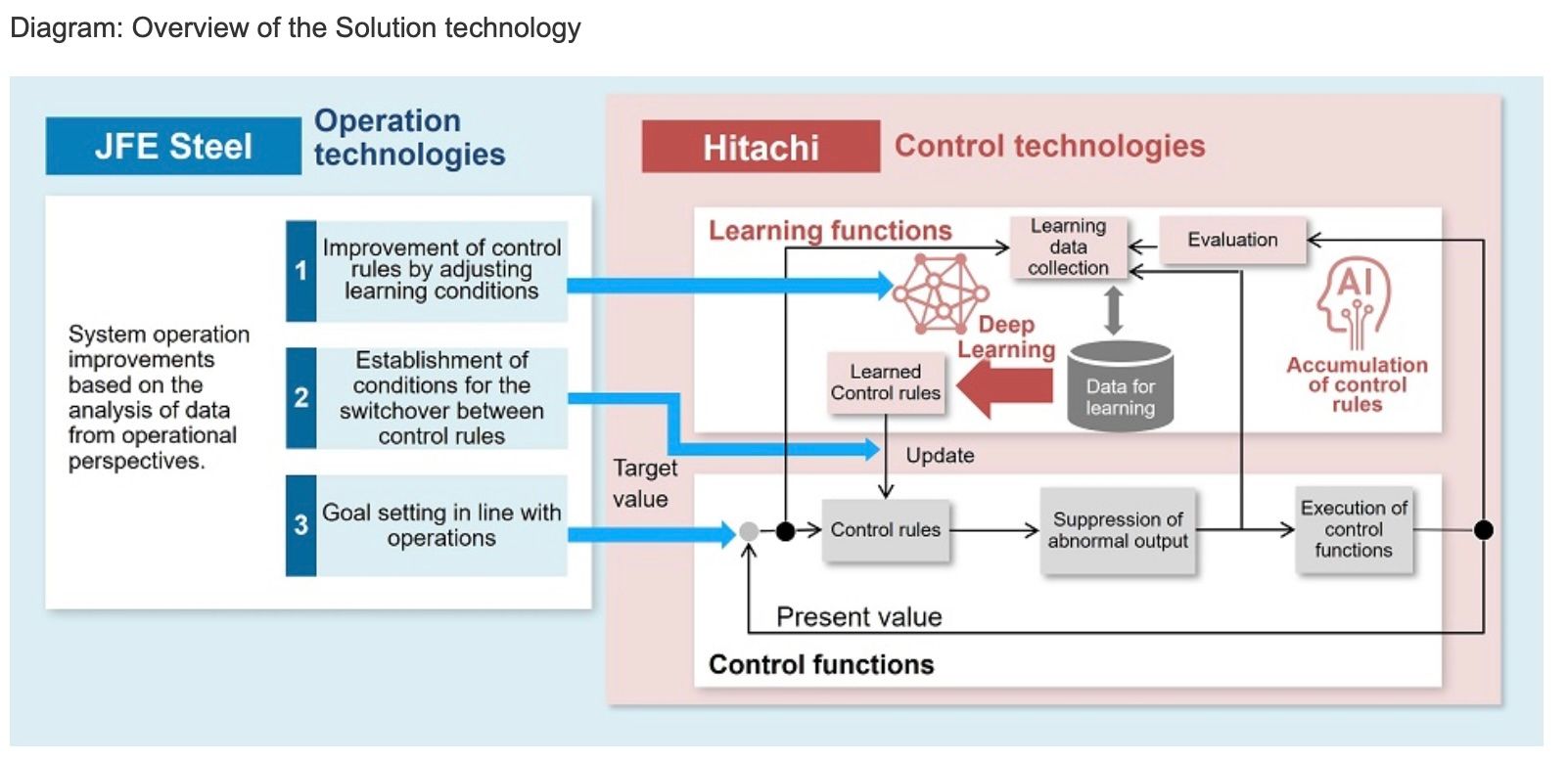

The switch of operators’ skills is a predominant self-discipline on the front traces of the steel manufacturing alternate, whereby a generational change is underway. To flatten wavy steel, which occurs at each and every facet or within the guts of a steel sheet sooner or later of the manufacturing of steel sheets, it’s a necessity for the operator to measure waviness and implement suggestions-primarily based mostly retain watch over whereas concurrently manually making graceful changes. Inexperienced operators glean it sophisticated to construct products with a host of form accuracy and quality requirements compared to skilled operators, that can lead to heart-broken product yield and breakage components ensuing from form defects. To manage with such components, Hitachi developed a technology that robotically performs excessive-quality form retain watch over in 2017*2, which parts a direction of whereby AI learns the connection between operational recordsdata about extremely skilled operators and recordsdata regarding the shapes of steel sheets, enabling the outcomes of this discovering out to be reflected within the output of the retain watch over procedure. It has been providing the technology as an computerized chilly-rolling flatness retain watch over procedure in Japan and additionally in a foreign country. JFE Steel launched the procedure on its production traces in 2021. Since then, it has been achieving a gigantic deal, equivalent to improved product yields, increased utilization rates and diminished operator workload through automation. Moreover, enabling the operational recordsdata and journey of skilled operators to be reflected in computerized processes led to increased productivity and the stabilization of product quality through the prevention of concerns.

Constructing on these outcomes, JFE Steel and Hitachi began to maintain the Solution combining the two companies’ strengths with a uncover toward addressing the components faced by their customers in chilly-rolling-primarily based mostly manufacturing. The two companies will work collectively to comprehend into consideration the configuration and maintain changes to the procedure that is terribly absolute top for customers’ set up.

(1) Lumada: A collective term for solutions, products and services and technologies consistent with Hitachi’s evolved digital technologies for rising label from customers’ recordsdata accelerating digital innovation

(2) Hitachi, Ltd. recordsdata release titled “Hitachi Develops Accurate-Time Administration Technology of Chilly Rolling Vegetation for Steel Vegetation Using AI” announced on October 31, 2017.

Contact:

JFE Steel Company

Contact Us (msgs.jp)

Hitachi, Ltd.Industry Contact

Inquiry make: Change

Copyright ©2024 JCN Newswire. All rights reserved. A division of Japan Corporate Info Community.